Steel belts for double belt presses

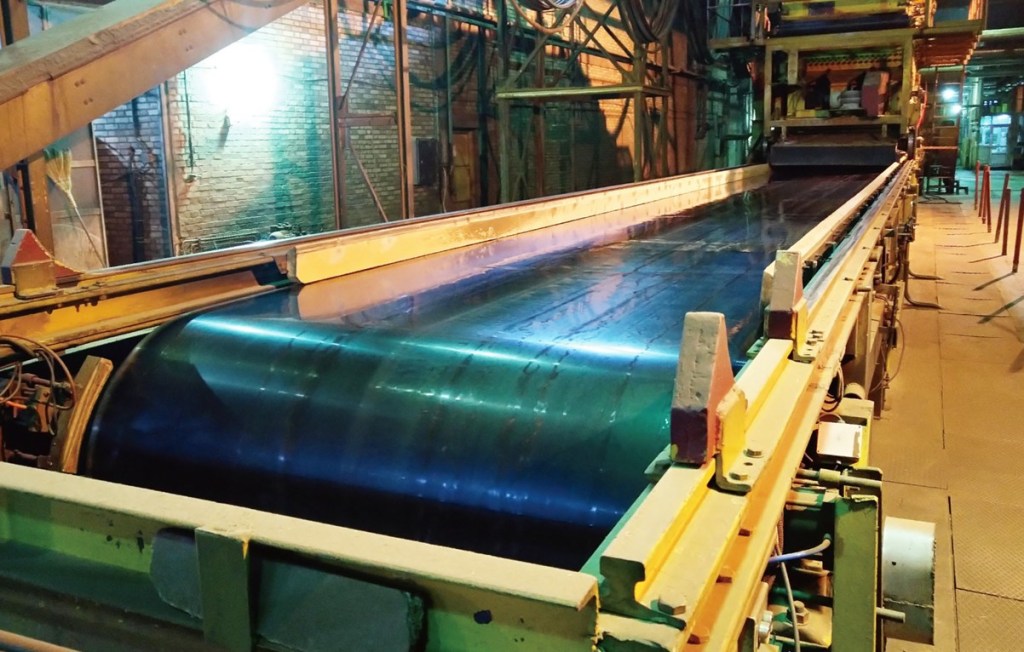

Wood-based panel flat pressing production lines adopt the double belt press system, which works by the upper and lower steel belts’ continuous operation. The steel belts for the wood-based panel industry have high tensile and fatigue strengths, hardness and good surface roughness and thermal conductivity, and the thickness variation, straightness and flatness are all excellent.

Steel belt dimensions

- Length ≤150 m/pc

- Width 1400~3100 mm

- Thickness 2.3/2.7/3.0/3.5 mm

Steel belt models

STEEL BELTS FOR MENDE PRESSES

The steel belt for Mende presses bears extremely high stresses due to continuous bending stress and thermal stress. The steel belt is bent four times and heated for each running cycle. The belt must be highly tensioned to exert high pressure onto the mat and panel.

Steel belt dimensions

- Length ≤150 m/pc

- Width 1400~3100 mm

- Thickness 1.8/2.0 mm

Steel belt models

STEEL BELTS FOR SINGLE OPENING PRESSES

Unlike other presses which are equipped with stainless steel belts, the single opening press adopts a carbon steel belt which is hardened and tempered, with good thermal conductivity yet low cost. These belts have a service life of more than 10 years.

Steel belt dimensions

- Length ≤150 m/pc

- Width 1400~3100 mm

- Thickness 1.2/1.4/1.5 mm

Steel belt models

Chromed steel belts for presses

In double steel belt continuous presses, the steel belt must withstand high pressure, intense friction and maintain precise performance. Chromium plating provides a tailored, high-performance surface treatment that enables the belt to operate reliably under these demanding conditions. The key benefits include:

- Enhanced durability – A hard chrome coating forms a tough protective layer, resisting friction and wear from moulds and materials. It withstands continuous pressures of several megapascals and high-speed cycles, reducing scratches and fatigue damage, extending service life and minimising downtime.

- Corrosion resistance – Exposure to air creates a dense Cr₂O₃ passive film, shielding the belt from water, oxygen, oils, cooling fluids and chemicals. This prevents rust and surface oxidation, ensuring clean production and stable product quality.

- Smooth mould release – The mirror-smooth chrome surface has very low adhesion, making it ideal for processing resin-impregnated composites and other specialist materials. It reduces release resistance, preventing slippage or damage, and improves production flow.

- Thermal stability – Chrome plating retains its properties up to 400°C, resisting thermal expansion, oxidation and performance loss during high-temperature operations.

- This advanced surface treatment enhances operational stability, process precision and product quality while significantly extending belt life and reducing long-term operating costs.

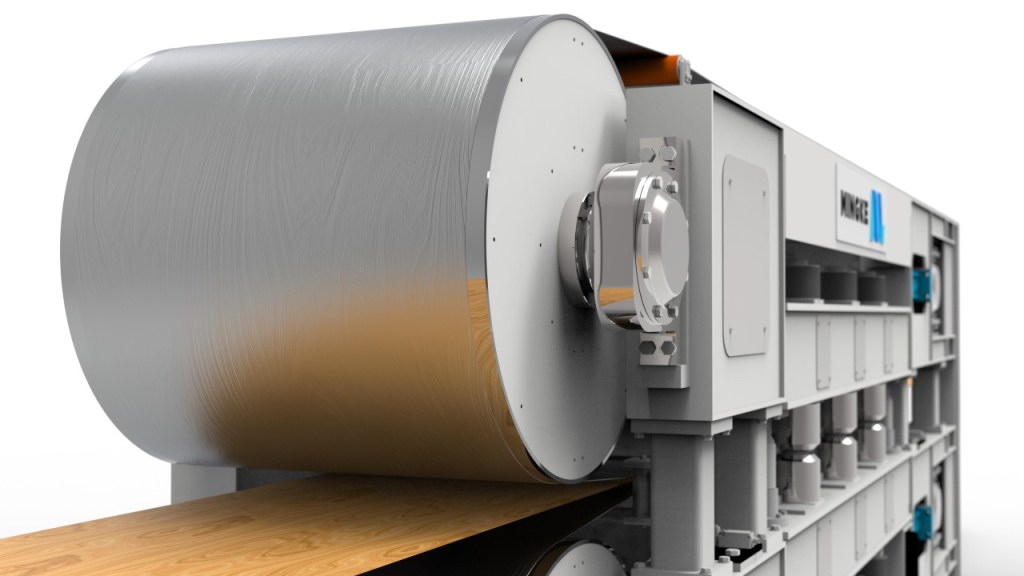

Rolling rods

Via our production partners Mingke, we are also able to supply rolling rods in various sizes.

For more information on how our products and services can help optimise your productivity, read our brochure.