To support the successful design, installation and operation of your steel belts, machinery and ancillary products, we offer the full range of technical support, including:

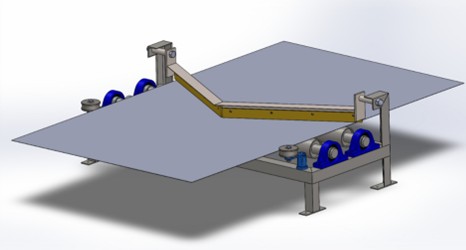

Design studio

Our in-house 3D CAD design studio enables fully bespoke end-to-end solutions, from conceptualisation, design and planning to operation, offering full management of your project.

Manufacture, installation and project management

A fully trained and Mingke accredited team will handle your steel belt and machinery installation, with Continuous Process Solutions alongside every step of the way offering full project management and customer liaison. We also oversee the manufacture and installation of any ancillary products.

Servicing and maintenance

Regular maintenance service intervals of your machinery, particularly belts, can detect root causes of trouble at an early stage and significantly reduce the wear on a system. Our regular maintenance and servicing will maximise the return on your investment and identify problems before they impact on your production. Our 20 years’ experience gives us the knowledge of the condition and limitations of your system.

Line and machinery inspections

We inspect individual lines, specifically those with solid or perforated steel belts, and issue a full report on our findings. We tailor recommendations with the aim of extending belt life and improving productivity. These are especially important for “troublesome” lines where tracking issues and excessive belt wear are apparent.

24/7 emergency response

For full peace of mind, we offer UK and Ireland-wide 24/7 emergency cover in the event of a malfunction.

For more information on how our products and services can help optimise your productivity, read our brochure.