Read real-life examples of how we have helped our customers protect their investment, increase productivity and reduce downtime.

Installing a new high performance belt for Reliable bakery production

Project location: North Lanarkshire, Scotland

Target industry: FMCG – Aberdeen Angus Pies

Belt type: Carbon steel (CT1300)

Production rate: Approximately 750 kg of pies per hour

A bakery customer had been operating an old, damaged conveyor belt in a large continuous-oven line production. Their existing conveyor system was showing signs of belt fatigue, wear, potential tracking issues and risk of unplanned downtime, all of which threaten throughput, product quality and maintenance cost. The extent of the damage and belt condition made repairs unviable, posing a risk of unplanned downtime and reduced operational efficiency. The bakery needed a belt solution that would reliably transport product through a 28-metre long tunnel, under high thermal and mechanical stress.

Continuous Process Solutions recommended the installation of a high-performance steel belt manufactured with appropriate materials and surface treatment for the bakery environment, specifically:

- A solid carbon or stainless steel belt made for continuous-oven use in bakery operations, capable of withstanding frequent temperature cycling, maintaining flatness and keeping product passing through smoothly (this aligns with known best practice for bakery oven belts)

- The belt length and installation were sized and engineered to ensure correct tracking, minimal deflection and robust long-term performance in the 28 meter oven.

- Ancillary support: proper belt tensioning, alignment and tracking systems, plus installation supervision by Continuous Process Solutions to ensure the belt system functions as designed

- Using a dedicated steel belt tailored for bakery continuous ovens offers longer life, greater reliability and lower total cost of ownership versus ad-hoc or generic belts. The correct choice prevents distortion, belt failure or product damage, and supports high throughput bakery production.

Following installation of the steel belt by Continuous Process Solutions, the bakery reported:

- Better total cost of ownership: the new belt solution is expected to have significantly extended service life and lower lifecycle cost compared to the prior arrangement

- Reliable continuous operation over the full 28 metre oven length, with no belt-related unplanned downtime since the upgrade

- Improved tracking and belt behaviour, reducing maintenance interventions and operator adjustments

- Enhanced product quality and consistency due to stable belt surface and heat-transfer behaviour.

Maximising your revenue – improving your belt product surface

Project location: Lanarkshire, UK

Target industry: FMCG/food manufacturing

Belt type: Solid steel

Pastry goods produced per hour: up to 1,000

An FMCG customer had an issue with a build-up of hard carbon on their solid belt product surface. Concerned with loss of revenue, they approached us for a solution to improve and maintain their product surface. We advised on a pneumatically operated belt-scraper, that would:

- Apply even pressure across the scraper

- Requires no further adjustments once set up

- Allows the blade pressure to be regulated to suit.

As demonstrated below, our design had an instant impact. We advised on the best practice to safely remove the build-up and improve the belt surface. The angle of the scraper knife to the belt is critical to ensure that the system is effective. Our 20 years of product knowledge has led us to understand the best design principles to protect and extend the belt life.

Working to a tight budget, rather than integrating the extend/retract function to their existing PLCs, we used a manual toggle switch for a no-nonsense operation. This format of belt scraper is a very cost-effective solution to maintaining a solid steel belt surface and is best installed with a new belt to maintain a clean product surface.

The importance of staying on top of your maintenance – drum bearings

Project location: South Wales, UK

Target industry: FMCG/food manufacturing

Conveyor length: 30m

Belt type: Solid steel

Sponge cakes produced per hour: >5 tne

Continuous Process Solutions was informed by a client with time constraints that a conveyor drum bearing had failed. We were contracted in to replace both take up drum bearings and time permitting, replace the two actuators which skew the drum position to make belt position corrections.

As continuous process specialists, we consulted the 3D CAD model that we have on file when considering the best method and tools. Aware that the clearance between the floor and the conveyor drum was a lowly 76mm, we ensured that our low-profile pallet truck was part of our equipment.

We were quickly able to establish the root cause. The shaft had been incorrectly locked down on both sides, causing undue stress on the bearings. Locking the drum shaft on one side only allows the drum shaft to be free-floating on the opposing side – necessary for when the drum position is skewed and not square to the frame.

Using tools specific for the job, we completed the task within the tight schedule and also had the time to replace the two large actuators, safety check the valves and have the line back up and running the same day. We also drilled and tapped the cast iron bearings to accept M12 screws to install bespoke plates which house the drum scraper assembly with a removeable debris catchment tray.

We can 3D CAD design and manufacture any item we recommend as part of our catalogue of works, checking parts and equipment before manufacture and installation.

We cannot stress enough the importance of ensuring that individuals are adequately trained for their specific roles. Should the customer have kept replacing these bearings and locking them in position, they would have continued to eat through both bearings and production time.

Don’t get caught out – routine maintenance identifies issues

Project location: Greater Manchester, UK

Target industry: FMCG/food manufacturing

Conveyor length: 72m

Belt type: Solid steel

Mini-cakes produced per hour: >52,000

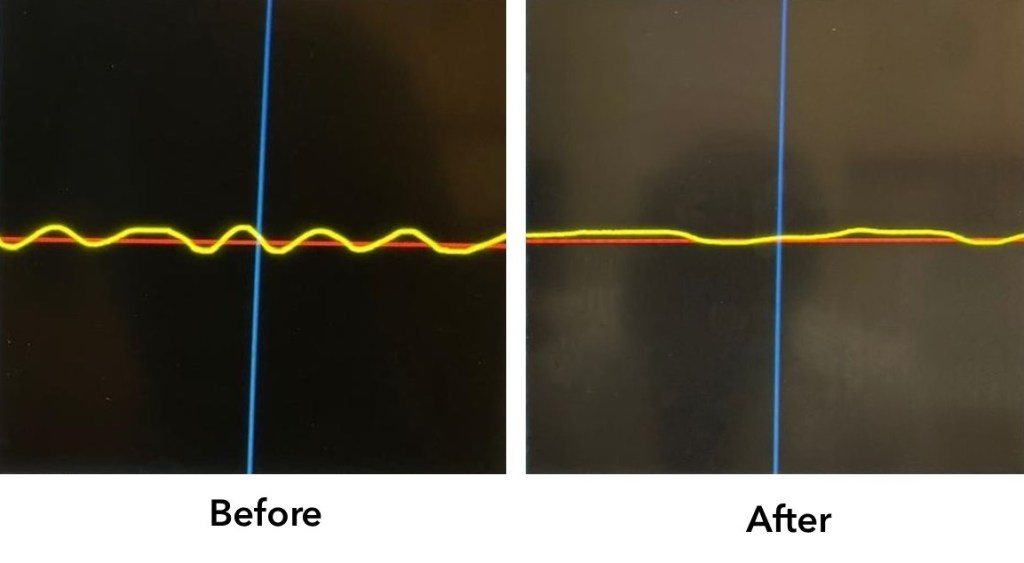

Continuous Process Solutions was requested to attend for a routine service and upgrade previously identified obsolete components. We were informed that the conveyor belt was out of position and asked to “clean” the guide rollers on the one side. We established that the control regulators had been altered out of machine tolerance, an attempt to improve the rate in which the tracking-tensioning system built up air pressure.

We identified that the customer’s ‘quick fix’ was the root cause of the problem. But what were the consequences for this quick fix?

Altering the flow regulators outside of our set tolerances had resulted in erratic conveyor belt position corrections causing violent movement, adding stress to not only the belt but also to the framework and additional equipment.

Unbeknown to the customer, those actions had caused the belt to collide with the internal guide rollers. Consequently, the customer was spending money treating cross-curvature sustained on the conveyor belt which was otherwise avoidable.

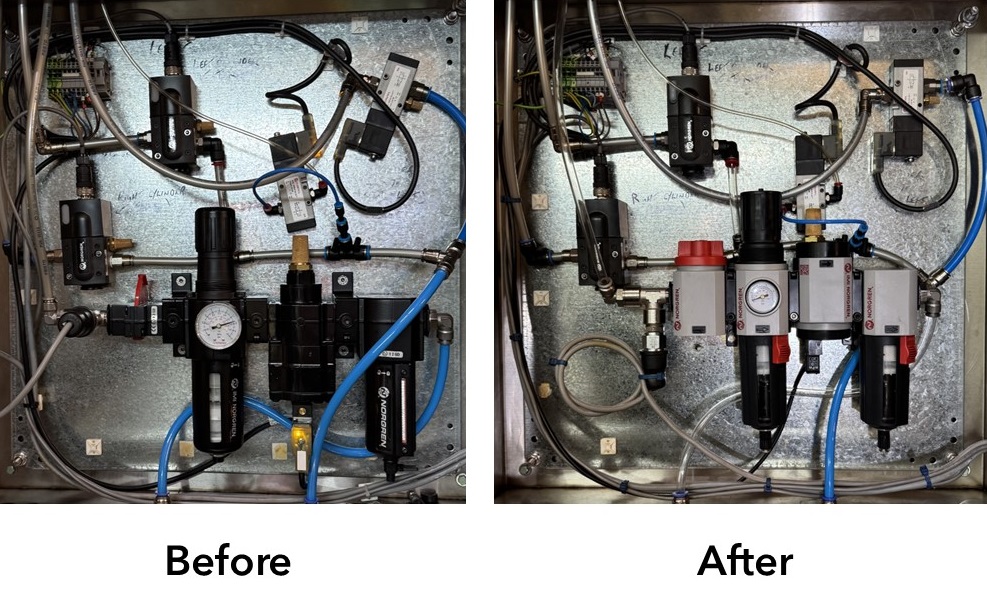

As conveyor system specialists, we were quickly able identify the root cause, thus saving the customer both time and money in the long term. We replaced the pneumatic pre–treatment block, removed the outdated, unsupported parts and commissioned a new soft/start dump valve. This means that sourcing replacement filter kits and parts will now be cheaper, having no long lead times.

Additionally, brand new particle filters were fitted to ensure that the pneumatic components are less vulnerable to pressure drops.

We also found oil and moisture contaminants in the electrical panel, so we tidied the panel. We stressed our findings, the causes for these issues and our recommendations, and a complete risk assessment was carried out and passed on to the customer.

The result of our service was a belt tracking system that exhausts and energises safely, in compliance with PUWER and the machinery directive, and a stable belt tracking system that will track the belt to tighter tolerances and avoid damaging the belt product surface.

If in doubt, leave it to the specialists. Endless repeatability is key in this game, so don’t get caught out.