Read our insights and opinions, ideas and expertise, information and updates on everything connected with the continuous process industry.

Engineered steel belts for bakery OVENS, IQF and cooling lines: maximise performance and margins

When designing or specifying food production lines — from bakery ovens to IQF and cooling/freezing systems — the components you choose directly affect project success, client satisfaction, and profitability. Steel belts, cleaning systems, and belt-tracking solutions are not just functional elements; they are strategic choices that influence quality, reliability, and long-term margins.

As the UK and Ireland experts in baked and frozen food processing, Continuous Process Solutions provides specialist steel belts and integrated systems that enhance line performance while offering cost savings of up to 22% compared with other suppliers.

Why choose Continuous Process Solutions for your projects?

Increase margins without compromising quality

Our steel belt solutions deliver equivalent or superior performance at lower cost, giving you an immediate opportunity to improve profit margins on every project.

Reliable performance across applications

- Baking, roasting and drying: Solid and stainless steel belts maintain product shape, prevent batter leakage, and ensure even heat transfer — ideal for tunnel ovens and continuous baking lines.

- IQF and cooling: Solid, perforated, and wire-mesh belts maintain consistent product flow, withstand thermal cycling, and minimise product sticking or damage in chilled and frozen environments.

Hygiene and cleaning built for every processing zone

- Hot-process zones: Purpose-designed scrapers, brushes, and bespoke cleaning systems manage residues, reduce manual cleaning time, and support HACCP compliance.

- Cold-process zones: Belt cleaning and scraper systems handle frost and residue, simplify access, and reduce manual intervention to maintain high hygiene standards efficiently.

Tracking and tensioning for longer service life

Misalignment and tension drift are leading causes of premature belt wear and unplanned downtime. Our in-house pneumatic tracking and tensioning systems keep belts aligned and tensioned correctly, protecting equipment and maintaining consistent production.

Full-system technical services and global support

We provide consultation, bespoke 3D CAD design, installation, commissioning, preventative maintenance, and 24/7 emergency support. Partnering with Continuous Process Solutions means a single, accountable supplier from project specification through to long-term operation — backed by a global leader for consistent quality and dependable availability worldwide.

Flexible purchasing and simplified vendor management

Whether your project requires a one-off order or a longer term supply agreement, working with a single supplier simplifies procurement, coordination, and ongoing support, giving you both operational and commercial flexibility.

Explore our solutions

Our brochure showcases steel belt types and typical installations across bakery, IQF and cooling lines. Contact us today, or we will be in touch to arrange an online or in-person meeting to discuss how Continuous Process Solutions can help you deliver high-performance, cost-efficient production lines.

Increase reliability, streamline supply and improve margins — all with one trusted partner.

Looking back on a brilliant 2025 at Continuous Process Solutions

What a year it has been! As we close the books on 2025, we are buzzing with pride at everything we have achieved together as a team, and with our partners and customers. From ambitious planning in January to industry-leading installations and award-winning success through the summer and into autumn, this year has truly been one to remember for Continuous Process Solutions.

January: setting our sights high

We kicked off the year in January with our annual business plan session, gathering colleagues from across the business to reflect, refresh and set our sights on the opportunities ahead. It was a chance to align around our goals, celebrate our strengths and map out our plan for growth in 2025. The ideas, energy and collaboration in that room set the tone for everything that followed – and we’re pleased to say that we have smashed the challenging targets we set ourselves, doubling our projected turnover.

April: a partnership that accelerates innovation

April brought one of the most exciting developments of the year: our partnership with Mingke. Inking the deal to become the sole UK and Ireland supplier of Mingke steel belts and process machinery was a major milestone for Continuous Process Solutions, giving us unrivalled access to world-class technology to support our customers. This collaboration has allowed us to expand our solutions portfolio and bring even greater capability and value to manufacturers across a wide range of sectors.

Summer success: awards and industry recognition

Summer 2025 was a season of celebration. In July, we were thrilled to be recognised at the Nachural Summer Business Awards, where we received a Highly Commended trophy in the Small Business of the Year category. Then in August, we proudly scooped the title of Best Steel Conveyor Solutions Company at the Midlands Enterprise Awards. We round off the year with news of shortlisting for another award, SME of the Year, at the Signature Awards Birmingham, with the winner announced next year. These accolades are a testament to the hard work, passion and expertise of our whole team, and we couldn’t be more proud.

Team growth: new faces, new ideas

One of the real highlights of 2025 has been the growth of our team. We have welcomed a number of new staff to the Continuous Process Solutions family this year, bringing fresh perspectives and skills that have already started to make an impact across the business. Whether in engineering, installation, office support or customer service, each new colleague has helped strengthen our capability to serve clients with excellence.

Standout projects: first Mingke belt installation

A particular operational highlight was the installation of our first Mingke belt at Bells Food Group. This landmark project demonstrated the power of our new partnership with Mingke in action, combining cutting-edge belt technology with Continuous Process Solutions’ installation expertise to deliver performance improvements on the ground. The success of this installation has opened doors for further projects and illustrated just how valuable this expanded offering is for manufacturers.

New products and services

Throughout the year we have also continued to innovate, expanding our product range with new belt technologies and services. From steel belt training programmes designed to boost uptime and capability for client engineering teams, to tailored inspection offerings, our focus has been on delivering real value and helping manufacturers improve efficiency and reliability.

Raising our profile: PR that delivers

2025 has also been a standout year for raising the Continuous Process Solutions voice across our industry. We secured an impressive 64 pieces of coverage in leading trade media, shining a spotlight on our expertise, projects and people. Alongside this, our team made regular editorial contributions, sharing practical insight and thought leadership on steel belts, process optimisation and manufacturing performance. We also took to the airwaves with our first ever podcast, with the London Food Network, opening up fresh conversations with industry peers and giving listeners a behind-the-scenes look at the challenges and opportunities shaping food manufacturing.

Looking ahead to 2026

As we look forward to 2026, we do so with real optimism. The foundations we’ve laid in 2025, from strategic partnerships and award recognition to team growth and standout project delivery, give us huge confidence as we continue to expand our reach and impact across the UK and Ireland. None of this would be possible without the hard work of our team, the trust of our clients and the support of our partners, and for that we are truly grateful.

From all of us at Continuous Process Solutions, thank you for being part of our journey this year. Here’s to a successful and exciting 2026 ahead!

Choosing the right belt for food production: why it matters and how Continuous Process Solutions can support your line

In food manufacturing, the conveyor belt is far more than a transport surface. It is a critical part of the process that influences product quality, hygiene, throughput and even energy use. Yet because belts are often considered background equipment, many operators continue using belt types that are not fully suited to their application, resulting in unnecessary downtime, inconsistent processing or avoidable maintenance costs.

Across the food industry, from baking and confectionery to IQF, cooling and dry goods, different belt technologies deliver very different results. Understanding those differences can make a remarkable impact on reliability and product consistency.

This is where Continuous Process Solutions comes in, supporting customers across the UK and Ireland. We supply, design and install belt systems that are engineered for specific applications, backed by cleaning, tracking and technical services that keep production running smoothly.

Below, we explore the most common belt types used in food processing and the applications where each one excels.

Solid steel belts: the foundation of consistency

Solid stainless or carbon steel belts are widely used in bakeries, chocolate lines and cooling systems. Their smooth, flat surface creates an exceptionally stable platform for products that require precise heat or cooling transfer.

Where they excel:

- Bakeries: Provide uniform heat transfer for even bake, prevent batter leakage, protect product shape and withstand high-temperature tunnel ovens.

- Confectionery: Deliver flawless cooling and surface finish for chocolate and sweets, avoiding marks and achieving consistent gloss or snap.

- Cooling and IQF lines: Offer controlled temperature transfer, reduce sticking and maintain product shape under thermal cycling.

Why customers choose them:

- Long service life in harsh environments

- Excellent hygiene characteristics

- Reduced deformation compared to plastic or fabric belts

- More predictable, repeatable processing conditions

- The ability to be cleaned thoroughly

Perforated steel belts: precision with airflow

Perforated belts are used where controlled airflow is needed, such as cooling tunnels, freezing lines, drying systems or certain cereal and sugar processes.

Where they excel:

- IQF processes: Improve cold air distribution, reduce moisture retention and support consistent freezing.

- Cooling and drying: Allow efficient heat exchange, support uniform product quality and help control moisture or temperature gradients.

Why customers choose them:

- Increased process efficiency due to enhanced airflow

- Reduced product sticking

- Better management of condensation and frost

- The ability to be cleaned, thanks to the flat working surface, whilst allowing heat flow through product.

Wire mesh belts: lightweight and versatile

Wire mesh belts offer flexibility, ventilation and controlled product support. They are often chosen for lightweight products or applications that require excellent drainage, airflow or minimal surface contact.

Where they excel:

- Cooling systems

- Transfer and enrobing

- Low weight loading environments

- Certain drying processes.

Why customers choose them:

- High ventilation

- Lightweight but durable design

- Cost effective for specific processes.

Beyond belt choice: why systems matter

Regardless of belt type, optimal performance depends on supporting systems that ensure hygiene, alignment and long-term reliability. This is where Continuous Process Solutions sets itself apart.

Cleaning systems to protect quality and hygiene

Residues are the enemy of product quality, whether it is sugar and cocoa in confectionery, crumbs and oils in bakeries, or frost and trace contaminants in IQF lines. Continuous Process Solutions supplies:

- Belt scrapers

- Brushes

- Non-product side belt ploughs

- Belt edge squeegees.

These systems:

- Reduce manual cleaning time

- Support HACCP compliance

- Lower contamination risk

- Improve process consistency

- Reduce chemical use

- Extend belt life for greater sustainability and better long-term value.

A cleaner belt means a more reliable line.

Tracking and tensioning: the hidden drivers of uptime

Misalignment is one of the top causes of belt wear and unplanned stoppages. Our pneumatic tracking and tensioning systems ensure belts stay correctly positioned under all operating conditions, including high heat, deep cooling or frequent thermal cycling. This leads to:

- Significantly extended belt life

- Fewer stoppages

- Better product placement and consistency

- Reduced replacement costs.

Full technical services: a single partner from concept to operation

Continuous Process Solutions does not simply supply belt hardware. We provide technical services that ensure each system is correctly specified, correctly installed and correctly supported. Our services include:

- Consultation and problem diagnosis

- Full 3D CAD design

- Installation and commissioning

- Preventative maintenance plans and servicing

- Training for maintenance and operational staff

- 24/7 emergency support.

Customers value having one partner responsible for system performance, with faster resolution and clear accountability.

What this means for your production line

Whether your products are baked, cooled, frozen, dried, coated or transferred, choosing the right belt and system provides measurable benefits. Our customers typically see:

- Improved product consistency and fewer rejects

- Higher hygiene standards with easier, faster cleaning

- Reduced downtime from belt wear or misalignment

- Longer belt and equipment life

- Simplified vendor management with one partner supporting the entire system.

Ready to improve your line performance?

Continuous Process Solutions supports every stage of your process, from oven to freezer. With precision-engineered belts, integrated cleaning and tracking solutions and full technical support, we help food manufacturers achieve cleaner, more reliable and more efficient production. If you would like to review your current belt performance or explore options for improvement, contact us to arrange a no obligation site visit or technical consultation. Let us help you build a more efficient, hygienic and resilient production line.

From belt to beyond: the power of the one-stop shop for continuous manufacturing

When it comes to running a high-throughput continuous processing line – whether for food, chemicals, wood-based panels, rubber, wax or anything in between – every link in the chain must be optimised. Downtime, inefficiencies or misalignment in one area can cascade across the whole line. That’s why at Continuous Process Solutions, we passionately believe in being a true one-stop shop for continuous solutions – from concept to commissioning and beyond. Let me walk you through what we mean by that, and why manufacturers across sectors are increasingly choosing to entrust their entire continuous process infrastructure to us, rather than juggling multiple contractors.

Why “one-stop shop” isn’t just a buzzword – it’s your competitive edge

1. Seamless accountability and coordination

Imagine you’re managing a bakery line. You contract one company to supply belts, another to install them, yet another to design the tensioning/tracking system, and still more to maintain and repair. Whenever something goes wrong, finger-pointing starts: “That installer damaged the frame,” “The belt supplier says the tracking is off,” “The maintenance contractor didn’t catch the root issue.”

By contrast, with Continuous Process Solutions, you have a single partner responsible for every stage: consultation, design, steel belt or conveyor supply, installation, belt monitoring and tracking, servicing, maintenance, emergency call-out. That consolidated responsibility means faster root-cause diagnosis, fewer coordination gaps and clearer accountability.

Because of our in-house design and project management, every component is chosen to match every other component, optimised from the start. That avoids that dreaded “interface friction” (literal and figurative) between disparate contractors.

2. Optimised integration of steel belts, machinery and ancillary systems

At Continuous Process Solutions, we don’t just supply steel belts – we provide full continuous process systems. That includes:

- Steel belts (solid, perforated, wire mesh) and the full range of ancillary equipment: cleaning brushes, scrapers, belt edge cleaners, spring-loaded diablos, graphite stations, belt supports, rollers and replacement drums.

- Machinery such as static isobaric double belt presses, flakers, pastillators and other Mingke equipment.

- We also handle belt tracking and tensioning systems – our in-house pneumatic belt tracking and tensioning system is designed to maintain precise alignment and extend belt life.

- And because all those parts are selected and assembled through a unified design, you avoid mismatches in dimensioning, control systems and interface points.

In effect, you get a harmonised system built for your plant from the ground up: not a patchwork of third-party parts.

3. Faster time to full operation, fewer surprises

Because we manage the full project, we can overlap design, manufacturing, installation and commissioning more efficiently. We anticipate on-site constraints, ensure dimensional coherence and align mechanical, electrical and control interfaces up front. In short: fewer “gotchas” on site, fewer delays and a smoother ramp up to full output.

4. Deep technical support from day one

We complement delivery with strong technical support:

- An in-house 3D CAD design studio, so bespoke challenges get bespoke solutions.

- Project management and customer liaison as we carry out manufacture and installation.

- Routine servicing, maintenance and line inspections to detect wear, misalignment and root causes before they escalate.

- 24/7 emergency response across the UK and Ireland – critical when a fault in a continuous line could shut down production in hours.

That continuum of support means that when something does go awry, our engineers already understand your system rather than having to reverse-engineer someone else’s installation.

5. Better lifetime value and lower total cost of ownership

A well-integrated system, correctly tracked, cleaned and maintained, lasts longer, wastes less, and demands fewer emergency repairs. Because we supply the full spectrum – from belt materials to maintenance – we’re incentivised to engineer longevity, not short-term margins.

Plus, by combining multiple scopes (supply, installation and servicing) under one roof, we can often deliver economies of scale and avoid duplicated overheads. That can translate to lower procurement, logistics and project management burdens for you.

6. Flexible, not locked in

We are not rigid gatekeepers. We build long-term relationships, not contracts that lock you in. Our approach is about partnership: you benefit from our full capabilities, but you’re free to evolve. We also maintain relationships with wire mesh belt and modular conveyor manufacturers, giving you choice when those options suit your process best.

What this means in practice — for food, chemical, wood-panel, rubber, and more

Food and bakery/IQF

In food production, hygiene, belt cleanliness, release behaviour and tracking tolerance are paramount. Continuous Process Solutions supplies solid or perforated steel belts, Teflon-coated belts for sticky or sugary items, and true tracking solutions (mechanical or V-rope) for IQF systems.

With a single partner managing design, belt selection, integration of cleaning systems, installation and ongoing servicing, you avoid hygiene blind spots, zone conflicts and belt misalignment issues that are common when multiple vendors are involved.

Chemicals, paints, powders and wax

In these sectors, belt chemistry compatibility, temperature control, flaking/pastillation equipment and robust belt cooling are critical. Continuous Process Solutions offers flakers, pastillators and other continuous machinery, and ensures your belt and ancillary systems are matched and integrated.

If a customer reports unusual wear or deposition, it’s not a question of “which contractor to call” – our own team handles it, supported by system data and shared responsibility.

Wood-based panels and composite press lines

The wood panel industry is demanding: double belt presses, resin impregnation, thermal gradients and belt durability are vital. Continuous Process Solutions is the exclusive UK and Irish agent for Mingke, and supplies carbon, titanium, stainless and chromed steel belts (for extended durability, mould release and corrosion resistance) tailored for double, single and Mende presses.

Because we can design your full press line integration, belt supports, tracking, cleaning and servicing, we eliminate misalignment, thermal stress and interface problems which typically plague multi-vendor systems.

Rubber and film casting

Rubber profiles, extrusions or continuous film processes demand belts that cope with thermal cycling, adhesion and precise control. Our combined offering – belt supply, cleaning, tracking and emergency support – ensures that you get a durable, stable, maintainable system rather than a fragile patchwork.

Modular and wire mesh conveyors, ancillary systems

We recognise that in many manufacturing lines, steel belts are just one link. That’s why Continuous Process Solutions maintains commercial relationships with wire mesh belt and modular conveyor manufacturers. When your process calls for a mesh belt section or modular conveyors adjacent to your steel belt route, we can coordinate or supply those seamlessly as part of your full line solution; you don’t have to go to another vendor.

Real-world proof: case studies in action

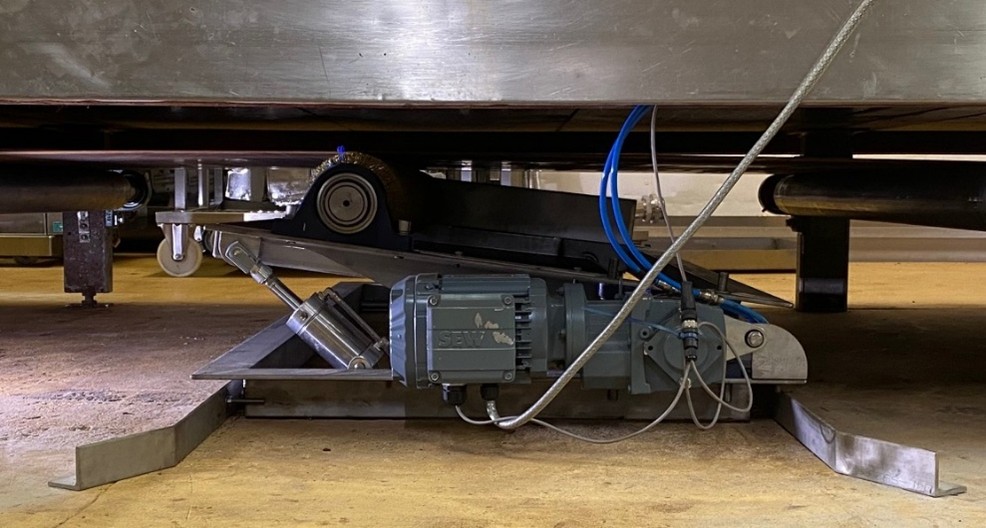

- In one food project, we solved a stubborn carbon buildup problem on a solid steel belt — designing and installing a pneumatically operated scraper with carefully calculated blade angle and pressure, giving immediate improvement.

- In another case, a failed drum bearing threatened to shut down a conveyor of sponge cakes. Because we already held the CAD model and knew the layout, we dispatched our low-profile tools and within the day replaced the bearings, actuators and recommissioned the line.

- Routine maintenance work on a 72m steel belt line revealed that the customer’s “quick fix” had actually altered tracking regulator settings beyond tolerance, causing violent belt motion and frame stress. We reversed the fix, commissioned proper controls, replaced obsolete parts and restored stability.

These are the kinds of proactive or reactive interventions that go more smoothly when one supplier has end-to-end system ownership.

In short: your continuous process partner, not just a contractor

At Continuous Process Solutions, we don’t want to be “just another belt supplier”. We want to be your continuous process partner – the one you call whenever you’re planning a new line, considering a retrofit or battling downtime. Because when one company handles consultation, design, supply, installation, training, maintenance and emergency service, you get:

- Clearer accountability

- Better integration and fewer interface surprises

- Faster commissioning

- Stronger ongoing support

- Lower total cost of ownership

- Greater resilience and flexibility.

If you’re running a food, chemical, wood panel, rubber or continuous process operation in the UK or Ireland, I’d love to explore with you how Continuous Process Solutions might simplify your supply chain, improve reliability, and reduce your risk. Drop me a line at jarrod@cpsuk.co or call 07729 505040, and let’s chart your continuous future together.

Here’s to never having to juggle ten contractors again – only one trusted partner.

Why sole supplier deals could be holding your business back

In industries which thrive on efficiency, innovation and competitive edge, locking your business into an exclusivity deal with a single supplier might seem like a safe bet. You get convenience, consistency and the promise of a “strategic partnership.” But scratch beneath the surface, and these agreements often reveal more drawbacks than benefits, especially for manufacturers in fast-paced sectors such as food, chemicals, wood-based panels, rubber and beyond.

At Continuous Process Solutions, we work with a wide range of customers who’ve come to us after feeling trapped in restrictive supplier contracts. Here’s why we believe sole supplier exclusivity deals are bad for business – and what you can do instead.

Reduced flexibility

Exclusivity ties your hands. If your only approved supplier experiences delays, product shortages or quality issues, your options are extremely limited. For manufacturers who operate in time-sensitive environments, that kind of bottleneck can mean missed deadlines, halted production and unhappy customers.

A more agile approach: Partnering with a flexible, independent supplier like Continuous Process Solutions means you can pivot quickly, source alternative components and keep operations running smoothly.

Poorer value for money

When your supplier knows they’re your only option, what’s their incentive to keep prices competitive? Many of our customers have discovered they’re paying well above market rates simply because they’ve lost the power to negotiate.

At Continuous Process Solutions, we consistently offer competitive pricing – and in some cases, considerably lower than sole-supplier agreements, without compromising on quality. Innovation stalls

Sole suppliers often focus on keeping the status quo. Without the pressure of competition, there’s little drive to introduce new technologies, improve materials or deliver smarter solutions. Your business needs partners who are pushing boundaries, not resting on laurels.

Innovation is in our DNA. We work with multiple partners alongside our main supplier Mingke, and continually seek out the latest developments in belts, tracking systems and process machinery so our clients stay ahead of the curve.

Lack of accountability

When there’s no alternative, there’s little accountability. If something goes wrong, or service levels drop, your leverage to challenge or change things is minimal.

At Continuous Process Solutions, we earn your trust with every single order. No long-term lock-ins – just great service, reliable products and a team that takes your success personally.

Hidden costs and risks

Exclusivity can bring with it a web of hidden costs, be they in higher pricing, slower lead times or the operational risks of being dependent on a single supplier’s logistics and supply chain.

Diversification is resilience. In today’s unpredictable global climate, spreading your supply risk isn’t just good practice – it’s essential.

Final thoughts

Sole supplier deals may promise simplicity, but they often cost your business in flexibility, value, innovation and resilience. At Continuous Process Solutions, we believe in giving our customers real choice, expert advice, and genuine partnership, without restrictive contracts.

If you’re rethinking your supplier strategy or want to see how much better things could be, get in touch. Let’s talk about smart alternatives that put your business first.

Ready for more flexibility and better value?

Contact us today at jarrod@cpsuk.co or call 07729 505040 to find out how Continuous Process Solutions can support your manufacturing success.

Why Conveyor Systems Are the Hidden Powerhouses of Food Manufacturing

Conveyors are often the unsung heroes of food production. While they might not grab the spotlight, their role in stitching the entire manufacturing process together is vital. A well-designed conveyor system uses space efficiently, keeps disruption to a minimum, and enables your workforce and equipment to operate at peak performance.

Start with the right layout

It’s easy to overlook conveyors when planning a plant layout, but doing so is a missed opportunity. As technology evolves, upgrading or reconfiguring your existing systems can significantly boost productivity. Sometimes all it takes is a fresh set of eyes to identify areas where improvements can be made – not just to the production flow, but to the overall efficiency of your line.

From racks to results: the power of continuous ovens

A great example of how conveyors can transform food manufacturing is the shift from rack ovens to continuous ovens. This simple change can more than double production output while also slashing energy use and operational costs. In today’s environment of high energy prices and green levies, those savings matter.

Continuous ovens also improve workplace safety and hygiene. With staff no longer handling hot racks, there’s a reduced risk of burns and contamination, and fewer ovens running means a smaller carbon footprint. As electric oven technology advances, this becomes an even more sustainable and desirable option.

Steel belts: the arteries of your line

In bakery and IQF (individually quick frozen) applications, think of the oven or freezer as the heart of the operation, and the solid steel conveyor belt as its main artery. Solid steel belts offer unmatched reliability and performance. They’re easy to clean, repair, and replace, keeping critical equipment running smoothly. Unlike chain, slatted or mesh belts, steel belts allow you to use the full width of the belt, maximising throughput.

Keeping things moving

Proactive maintenance is key to avoiding costly downtime. Engineers should regularly inspect key components – bearings, drives, drums and all elements that come into contact with the belt. Proper alignment reduces wear, and tracking systems help prevent heat-related issues. Installing and maintaining cleaning brushes and scrapers from the start helps reduce carbon build-up and extends the life of your belt. For example, one of our clients. a well-known baked goods manufacturer in the south of England, installed a steel belt with scraper and tracking systems. They’ve since seen their belt’s lifespan triple.

Get expert support

Finally, don’t go it alone. Tap into your industry network and work with experts to support your in-house engineering team. Establishing a regular service cycle is a simple yet powerful step towards long-term efficiency.

experiencing build up of carbon and other contaminants on your belts?

Carbon deposits and other contaminants cause problems with solid steel and mesh belts, leading to contamination, adhesion, a loss of belt performance, line downtime and costly repairs or even replacement.

What causes the issue?

Carbon builds up when product, fat, grease or release agents are not cleared from the working surface. The carbon build up creates a sticking point for the newly laid product and what starts as a small spot gets larger: the spot is baked continuously through the oven and in turn, more product, fat and oils adhere to the area. These are then baked continuously until they also become carbon, increasing during every revolution, and expanding until the whole band either has a strip or large areas covered in carbon.

What are the implications?

This not only creates a product adhesion problem but also a cross-contamination issue, and can also impede the belt performance. The carbon areas absorb heat, creating hot spots which cause uneven thermal expansion of the band. This causes tracking issues, making the band unstable during operation. In extreme circumstances, the band can wander in either direction and eventually collide with oven internals or exterior framework. This will take the line down for hours, possibly days, until a repair can be affected. However, the issue will still be present even after the repairs and will be experienced once more.

So what’s the solution?

There is a simple yet effective solution to this problem: correct belt cleaning. This can be in the form of a brass scraper system, or a cleaning brush arrangement.

The scraper system needs to be installed correctly and more importantly at the correct angle, ideally when a new belt is fitted. This will reduce existing carbon deposits, or prevent them if installed with a new band. We have developed a cost-effective solution to the correct angle to ensure carbon issues are vastly reduced. The system uses a pneumatic piston to control the amount of pressure applied to the oven band, and even problematic bands will benefit from this system.

For more stubborn bands or harsher environments, we recommend one of our cleaning brush systems. The brushes have interchangeable heads where different bristle diameter or patterns can be added, dependent upon the type of issues and severity.

We are the UK’s leading specialist in continuous process manufacturing equipment, with two decades of experience and expertise with solid, perforated and wire mesh conveyor belts, bringing cost-effective smart solutions to the FMCG manufacturing sectors. Contact Jarrod and the team today.